The concrete

flooring work is a complex process that demands precision and efficiency.

This is largely facilitated by the use of specialized machinery, each designed

to perform specific tasks in the construction process. From mixing concrete to

final finishing, these machines play a crucial role in ensuring the quality and

durability of the floor. Here are five essential machines commonly used in

concrete floor construction:

Concrete Mixer

A fundamental tool in any concrete work, the concrete mixer

is essential for combining the raw materials (cement, water, aggregate, and

sand) to form a consistent concrete mix. These mixers come in various sizes,

from small portable units ideal for small projects to large, truck-mounted

mixers used for extensive construction sites. The key is to achieve a uniform

and well-blended concrete mixture that meets the project’s specific requirements.

Power Trowel

Once the concrete is laid, a power trowel is used to smooth

and level the surface. This machine consists of one or more rotating blades and

is available in walk-behind and ride-on models. The power trowel is essential

for achieving a flat and smooth finish, especially in large areas where manual

troweling is impractical.

Concrete Vibrator

To ensure that the poured concrete is compact and free of

air bubbles, a concrete vibrator is used. This machine consolidates the

concrete and eliminates unwanted air pockets that can weaken the concrete

structure. The vibrator is typically used after pouring the concrete and before

it begins to set, ensuring a more homogenous and stronger concrete slab.

Screed Machine

A screed machine is used to level and smooth the top layer

of concrete after it has been poured. Screeds come in various types, including vibrating concrete

screeds that provide a more uniform finish. This machine ensures that the

concrete surface is flat and even, which is critical for the integrity and

appearance of the floor.

Concrete Saw

For cutting expansion joints or making precise cuts in

concrete, a concrete saw is indispensable. These saws can cut through hardened

concrete quickly and accurately, which is vital for preventing cracks and other

structural issues. Concrete saws come in different sizes and can be powered by

electricity, gasoline, or hydraulics, depending on the project's needs.

In conclusion, the use of these machines in concrete floor

construction not only enhances the efficiency and speed of the construction

process but also significantly improves the quality of the final product. Each

machine serves a specific purpose, from mixing and laying to finishing and

cutting, ensuring that every phase of the concrete floor construction is

executed with precision. Mastery of these machines is essential for any

construction team aiming to deliver durable, high-quality concrete floors.

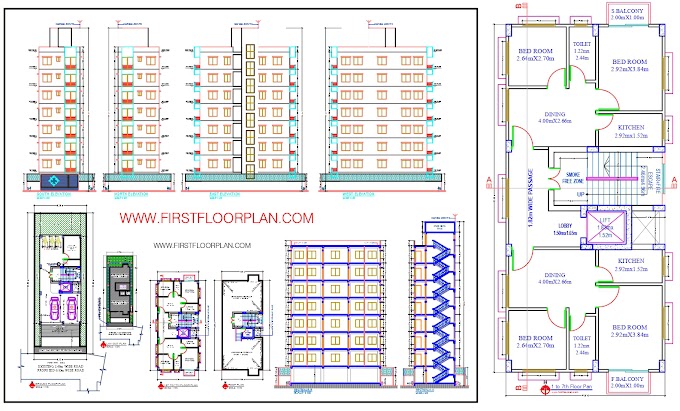

%20House%20plan%20with%207%20storey%20Apartmen%20building%20Structural%20desing%20%20DWG%20&%20PDF.jpg)

0 Comments

Write Your Comment Here..